|

||

| Sulphuric Acid on the WebTM | Technical Manual | DKL Engineering, Inc. |

Knowledge for the

Sulphuric Acid Industry

![]()

Sulphuric Acid on the Web

Introduction

General

Equipment Suppliers

Contractor

Instrumentation

Industry News

Maintenance

Acid

Traders

Organizations

Fabricators

Conferences

Used

Plants

Intellectual

Propoerty

Acid

Plant Database

Market

Information

Library

Technical Manual

Introduction

General

Definitions

Instrumentation

Plant Safety

Metallurgial

Processes

Metallurgical

Sulphur Burning

Acid Regeneration

Lead Chamber

Technology

Gas Cleaning

Contact

Strong Acid

Acid Storage

Loading/Unloading

Transportation

Sulphur

Systems

Liquid SO2

Boiler Feed Water

Steam Systems

Cooling Water

Effluent Treatment

Utilities

Construction

Maintenance

Inspection

Analytical Procedures

Materials of Construction

Corrosion

Properties

Vendor Data

DKL Engineering, Inc.

Handbook of Sulphuric Acid Manufacturing

Order

Form

Preface

Contents

Feedback

Sulphuric Acid

Decolourization

Order Form

Preface

Table of Contents

Process Engineering Data Sheets - PEDS

Order

Form

Table of Contents

Introduction

Bibliography of Sulphuric Acid Technology

Order Form

Preface

Contents

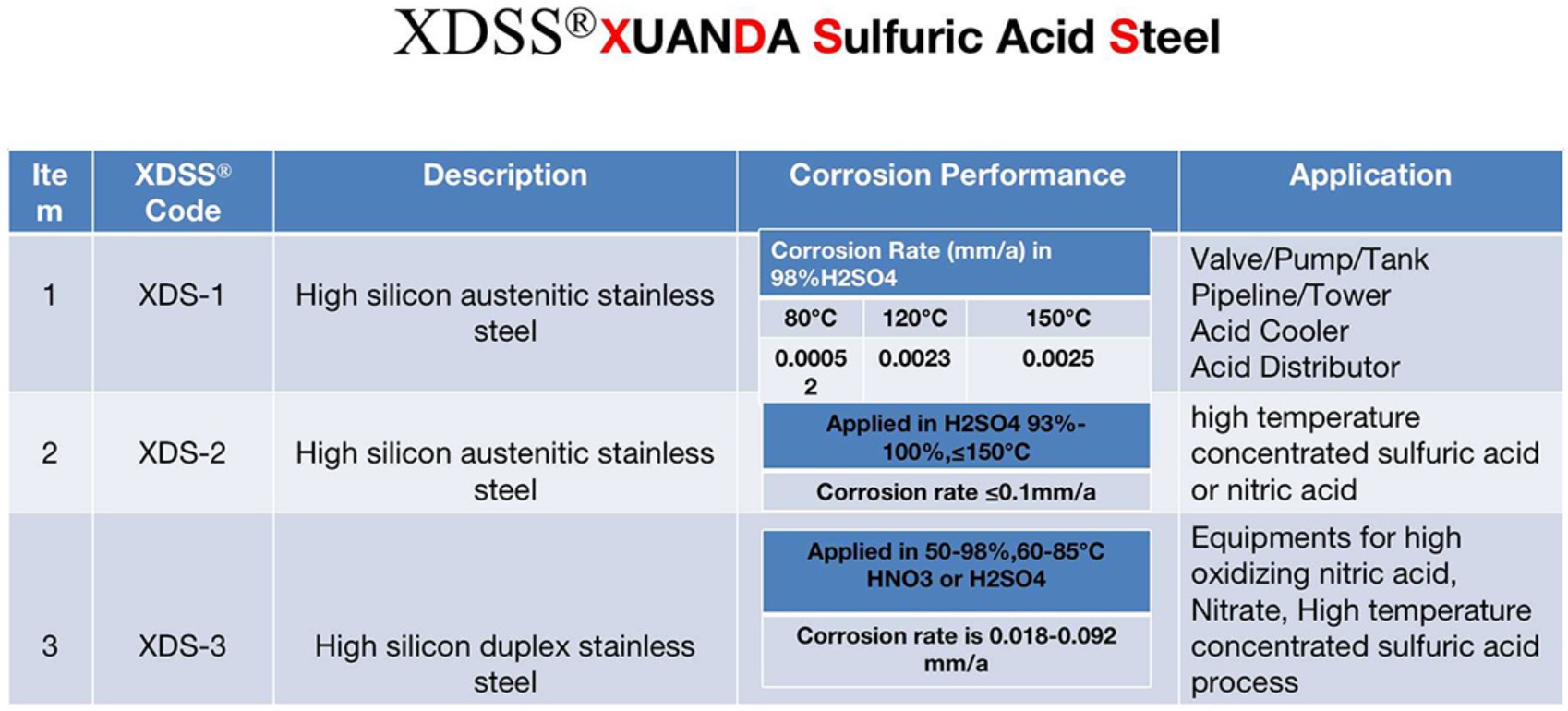

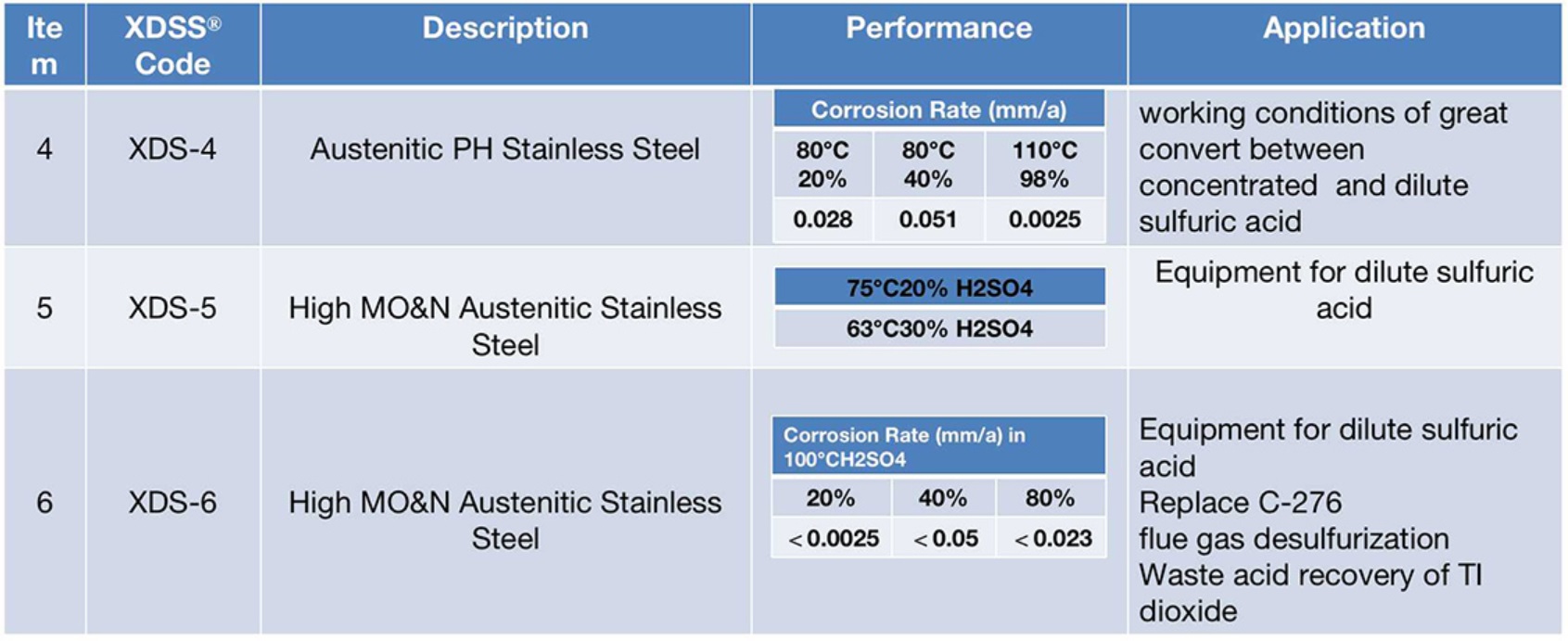

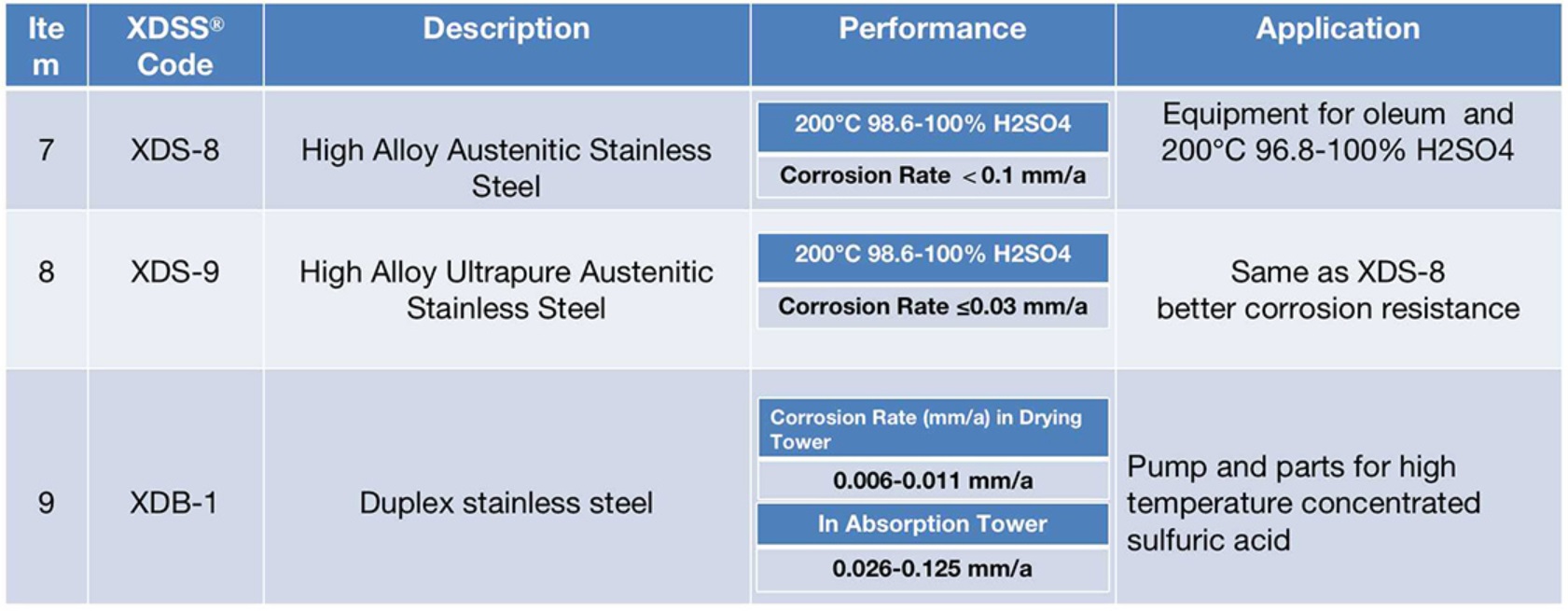

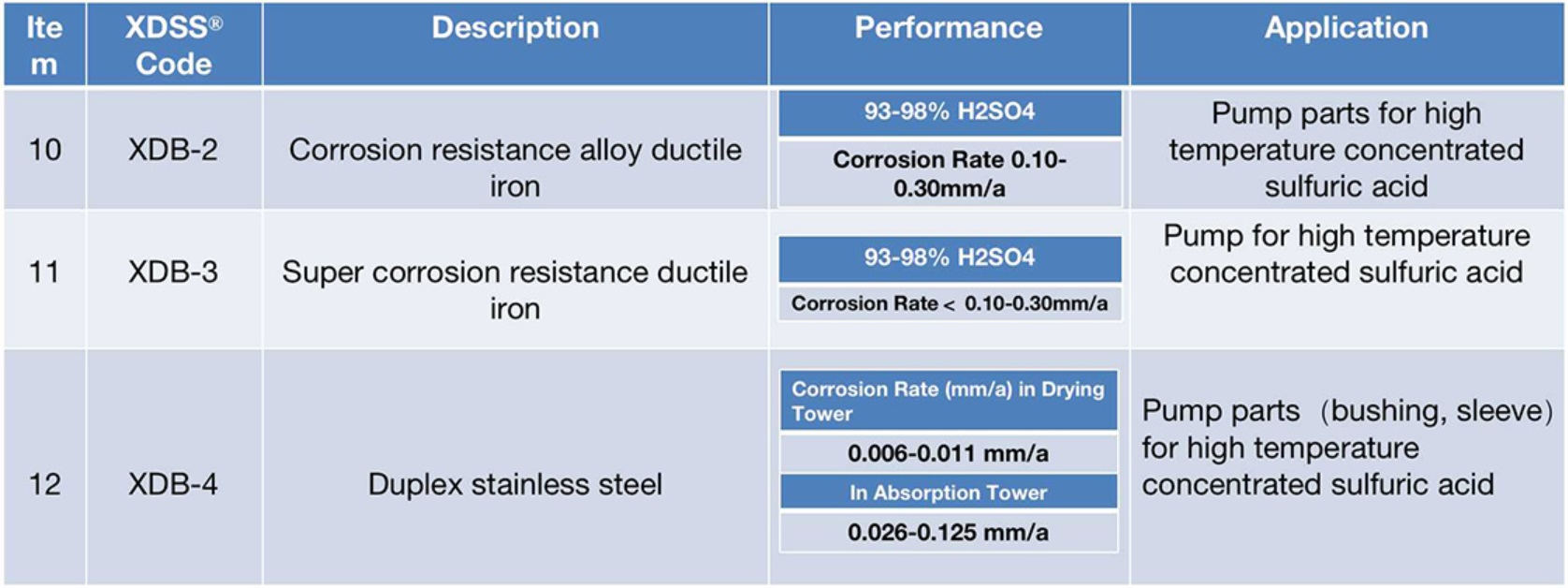

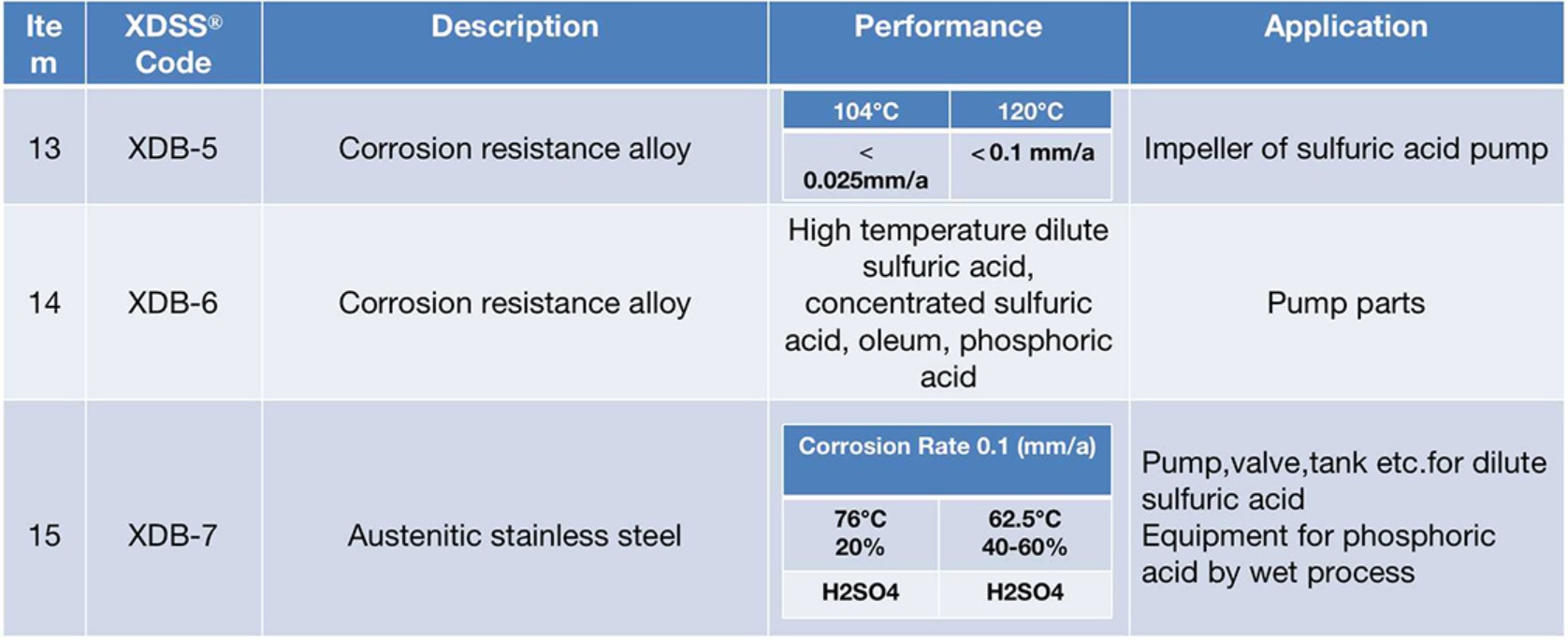

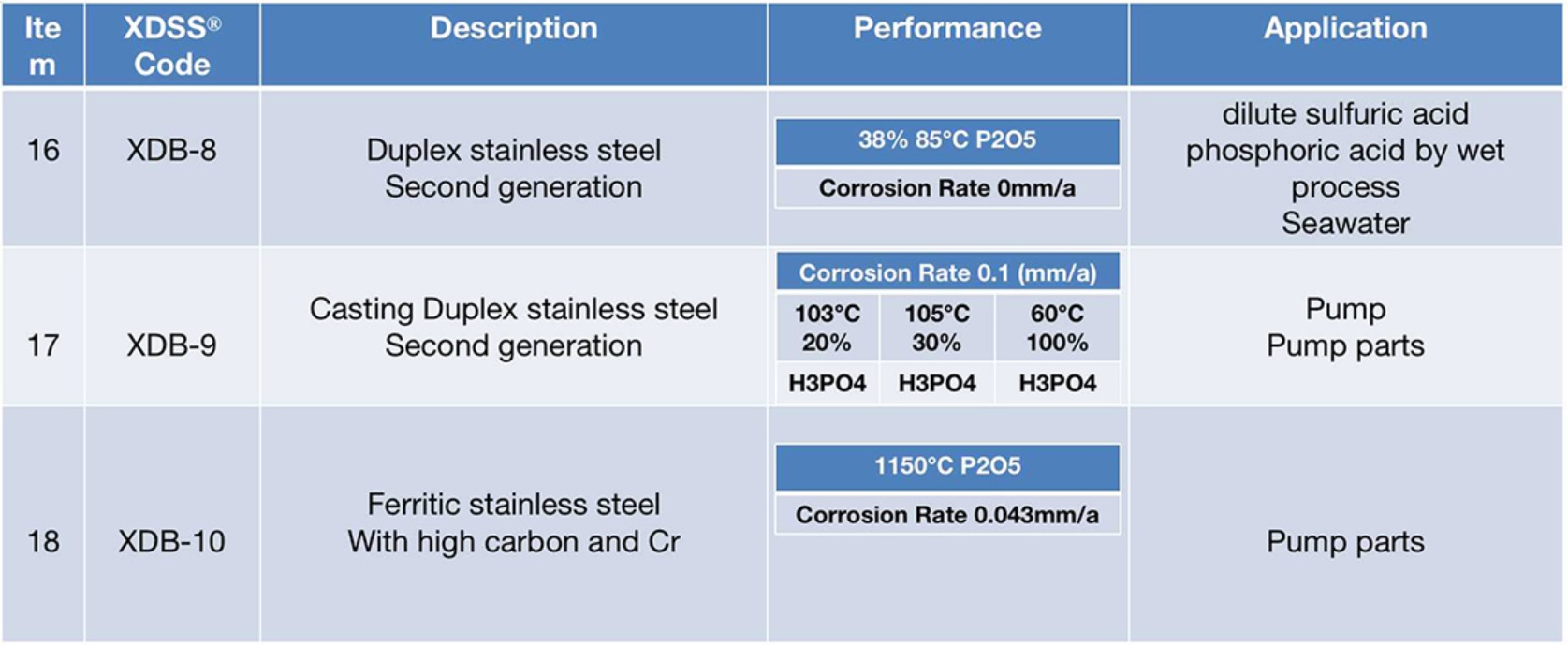

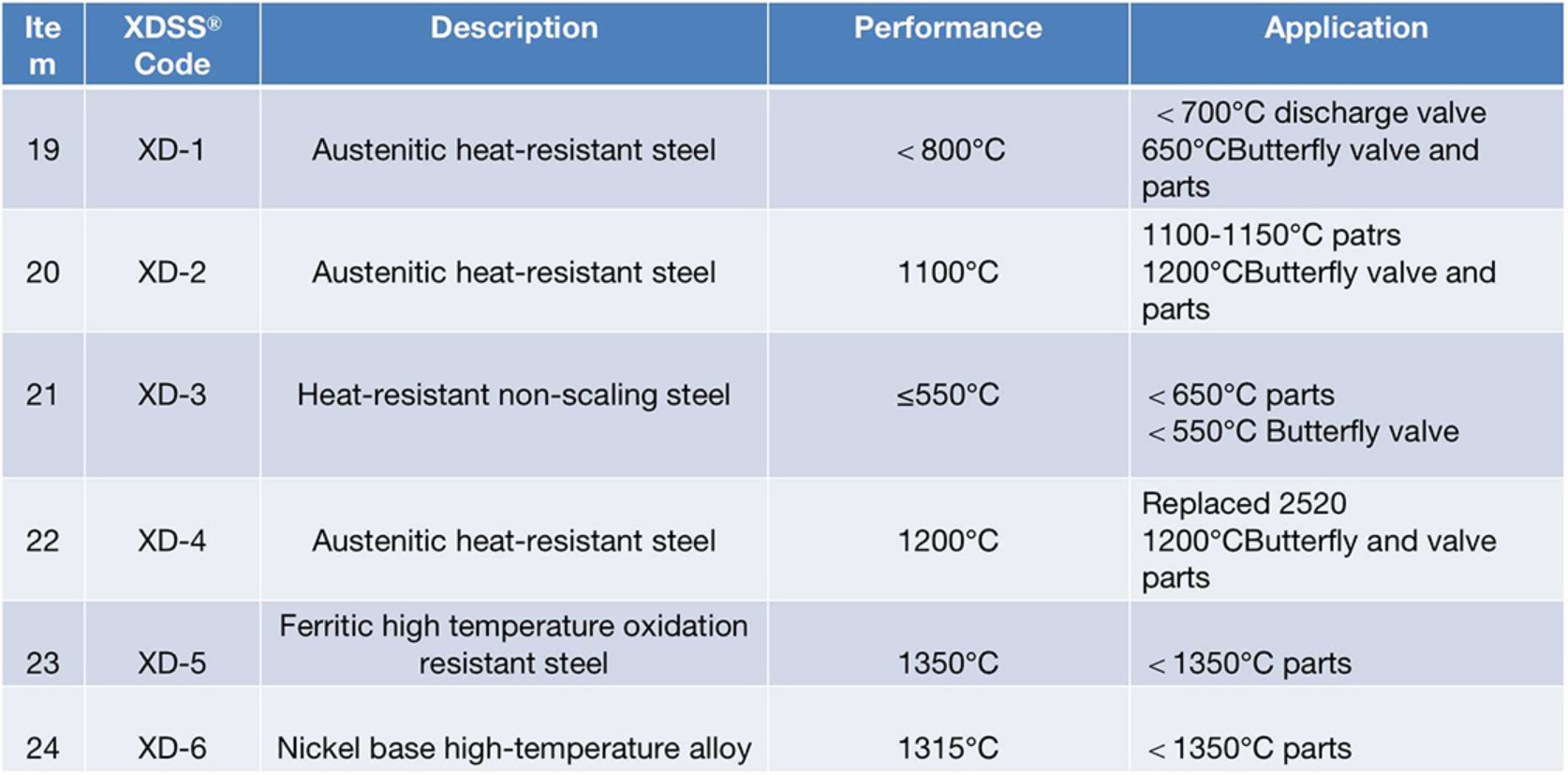

Materials of Construction - XDSS Alloy

System

December 15, 2023

|

Introduction |

Associated

Links www.xuanda.com |